Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

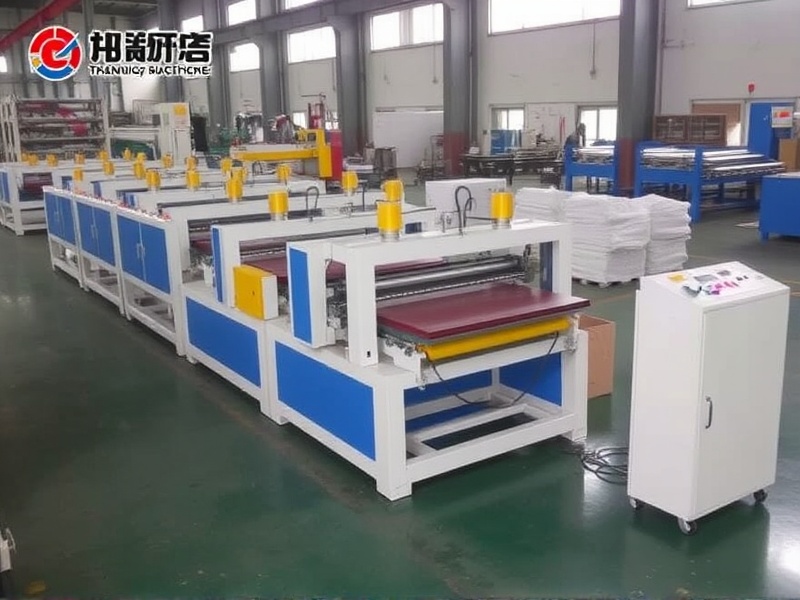

Discover leading suppliers providing competitive wholesale WPC sheet machine prices that can meet the demands of both small-scale and large-scale manufacturers.

Wood Plastic Composite (WPC) sheet machines are essential tools for manufacturers looking to produce high-quality composite materials. These machines combine wood fibers with plastic to create a durable, weather-resistant product that is widely used in construction, furniture making, and other industries. The demand for WPC products has been increasing steadily over the years, driven by their eco-friendly nature and low maintenance requirements. As a result, choosing the right supplier of wholesale WPC sheet machines can be crucial for businesses aiming to enter or expand in this market.

In the competitive landscape of WPC sheet machine suppliers, several companies stand out due to their innovative technologies, robust machine specifications, and comprehensive service packages. Here, we explore some of the top players in the industry:

Supplier A is renowned for its cutting-edge technology and reliable machinery. Their WPC sheet machines boast advanced extrusion systems capable of producing sheets up to 3 meters wide with thicknesses ranging from 2mm to 20mm. Additionally, they offer a range of customization options, allowing clients to tailor the machines to their specific needs. Supplier A also provides extensive training and after-sales support, ensuring that customers can operate the machines efficiently from day one.

Supplier B focuses on delivering high-capacity machines designed for large-scale production. Their flagship model can process up to 1000 kg of raw material per hour, making it ideal for factories requiring high output volumes. The durability of their machines is another key selling point; built with heavy-duty components, they are designed to withstand continuous operation under demanding conditions. Furthermore, Supplier B offers a two-year warranty on all machines, providing peace of mind for buyers.

Supplier C distinguishes itself through its all-inclusive service package. Beyond the standard features, they include regular maintenance checks, software updates, and even a dedicated customer service team available 24/7. This holistic approach ensures that customers receive not just a machine but a complete solution for their manufacturing needs. Their WPC sheet machines are equipped with user-friendly interfaces and have a production capacity of up to 800 kg per hour.

Each of these suppliers brings unique value propositions to the table. Supplier A emphasizes innovation and customization, Supplier B focuses on high capacity and durability, while Supplier C offers an unparalleled service package. When considering which supplier to choose, it’s important to evaluate your business needs carefully. For instance, if you prioritize flexibility and customizability, Supplier A might be the best fit. Conversely, if your primary concern is maximizing production volume, Supplier B could be more suitable.

The selection of a wholesale WPC sheet machine is a critical decision for any manufacturer entering or expanding in the WPC industry. By understanding the key offerings and unique selling points of leading suppliers like Supplier A, Supplier B, and Supplier C, businesses can make informed choices that align with their specific requirements and goals. Remember, investing in the right equipment can significantly impact your operational efficiency and long-term profitability.

IndustryWeek – Choosing the Right Manufacturing Equipment for Your Business