Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

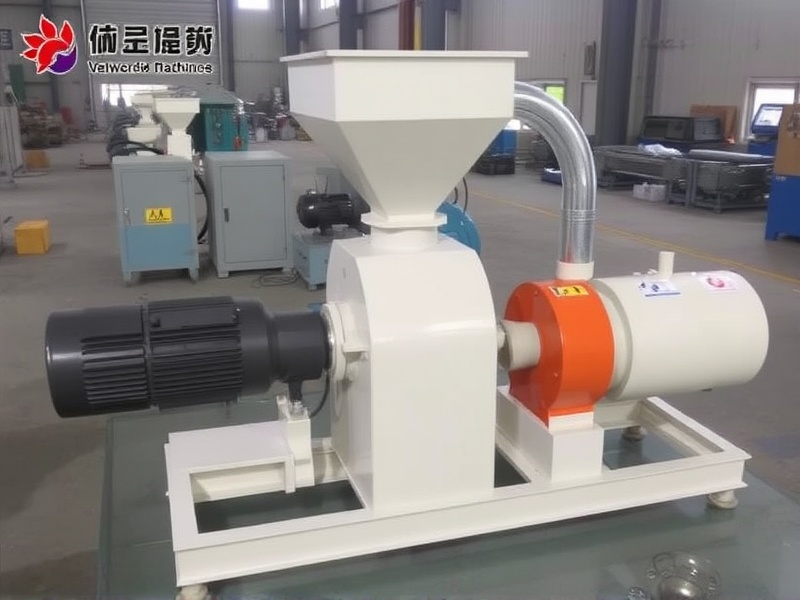

Discover how China's advanced WPC granulator machines enhance the production of wood plastic composites, contributing to sustainable building materials.

The global push towards sustainable development has led to a significant increase in the demand for Wood Plastic Composite (WPC) materials. These materials are increasingly being used in construction and other industries due to their durability, low maintenance requirements, and eco-friendly nature. The production of WPC materials involves several steps, one of which is the use of WPC granulator machines. This article delves into the features and benefits of China-made WPC granulator machines, discussing their pivotal role in the production process, their environmental impact, and how they contribute to the growth of the sustainable construction industry.

China-made WPC granulator machines have become synonymous with innovation and efficiency. They are designed to handle a wide range of raw materials, including wood fibers and plastics, making them versatile tools in the production of high-quality WPC products. These machines are equipped with advanced features such as high torque motors, automatic feeding systems, and precision cutting blades. These components ensure that the material is processed uniformly, resulting in consistent granules that can be easily molded into various shapes and sizes.

One of the key benefits of using these machines is their ability to enhance productivity while reducing operational costs. By automating the granulation process, manufacturers can achieve higher throughput rates, leading to increased production volumes. Additionally, the efficient design of these machines minimizes energy consumption, contributing to lower operating expenses and a smaller carbon footprint.

The production of WPC materials typically involves mixing wood fibers with thermoplastics, followed by extrusion and shaping processes. The granulator machine plays a crucial role in this process by converting the mixed material into small pellets or granules. This step is essential as it ensures uniformity in the composition of the final product, which is critical for achieving desired properties such as strength and flexibility. Moreover, the granules produced by these machines are easier to transport and store compared to bulk materials, thereby optimizing logistics and storage operations.

The environmental benefits of using China-made WPC granulator machines cannot be overstated. These machines help reduce waste by efficiently processing raw materials into usable granules. Furthermore, since WPC materials are derived from recycled wood and plastic, their production contributes to the reduction of landfill waste and the conservation of natural resources. This aligns perfectly with global efforts aimed at promoting sustainable practices within the construction industry.

The adoption of WPC granulator machines has played a significant role in advancing the sustainable construction sector. As awareness about the environmental impact of traditional building materials grows, more architects and builders are turning to WPC materials as viable alternatives. The use of these materials not only reduces the strain on forests but also decreases reliance on petroleum-based plastics. Consequently, the widespread implementation of China-made WPC granulator machines supports the development of greener infrastructure, fostering a more sustainable future.

“Sustainability Assessment of Wood Plastic Composites: A Case Study”